Labyrinth Seals

Non-contact seals for dirt and contaminants exclusion

For sealing dynamic, rotary motion

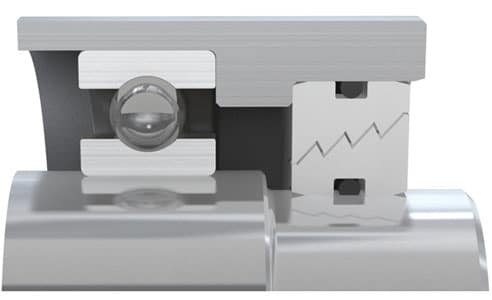

Labyrinth seals use a non-contact seal design and are specifically designed to protect bearings from splashing water and other contaminants. These seals are …More Info not designed to seal pressure differentials or to seal against high fluid levels. They are primarily for contaminants exclusion. They consist of a stationary and a rotating ring and are made of engineering plastic or other high performance polymer materials.

Non-contacting rotary and stationary elements seal statically press-fit into the bore and/or on to the shaft and provide a restricted flow path through the controlled labyrinth gap based on a conic design and utilizes centrifugal force and gravity to prevent intrusion of contaminants into the bearing chamber. Unlike common lip seals, the labyrinth seal will not damage shafts and has a virtually unlimited life. It is very important that the labyrinth seal is mounted correctly. The bigger labyrinth diameter must be pointing to the contaminants.

Benefits of labyrinth seals are:

- No contact, no wear and heat generated by the seal, no frictional power loss

- Reduced maintenance cost since no wear, almost unlimited life

- Low cost for mating parts, no hardening and surface grinding of the shaft required.

- Available in FDA compliant materials

- Chemically resistant grades available

- Overall a very economical sealing solution taking all the above in consideration

- Low cost replacement for other expensive labyrinth seals in many applications

Labyrinth Type Seals

Typical Applications

Food processing machinery, electric motors, machine tools, semiconductor industry, packaging, food processing, textile, pharmaceuticals, conveying equipment, protection for primary seal

Operating Range

Pressure: Zero

Surface Speed: Up to 10,000fpm (50m/sec.)*

Temperature: -60 to 400°F (-50 to 200°C) depending on seal material

Materials: engineered plastic composite, metal, FDA materials

Availability: More Info…

Please contact engineering for details.

*Maximum values depend on seal material, seal configuration, media, temperatures, pressures, surface speed and working environment. For maximum seal life expectancy, do not operate your seal beyond 75% of any of its operating limits. Please contact engineering or call 1-800-283-7140 for advice.

American High Performance Seals assumes no obligation or liability for any advice furnished or results obtained with respect to these products. All such advice is given and accepted at the buyer’s risk.

This information, based on our experience, is offered as part of our service to customers. It is intended for use by persons having technical skill, at their own discretion and risk. We do not guarantee favorable results, and we assume no liability in connection with its use.