Hydraulic & Fluid Seals

Piston Seals

For linear and reciprocating dynamic sealing applications

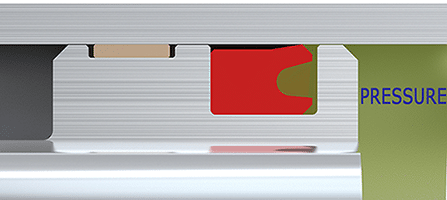

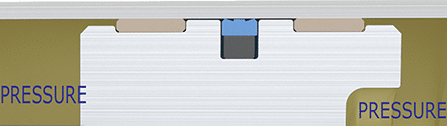

The function of the piston seal is to ensure that pressurized fluid or other media does not by-pass the piston as the system pressure pushes the piston down the cylinder during a pressure cycle.

American High Performance Seals manufactures a comprehensive range of piston seal designs, including lip seals, PTFE cap seals, compact-squeeze type seals and application–specific designed seals made from high-performance elastomers and engineered plastic materials to offer maximum durability and sealing performance.

Piston Seal Design Considerations:

• Pressure Rating…

• Pressure Rating

Pressure Rating

The maximum pressure rating of seals is greatly influenced by many factors:

– Extrusion gaps, clearances:

The extrusion gap is defined as the maximum radial clearance on one side between the seal housing opposite of pressure and the sealing surface. The extrusion gap is the most pressure-limiting factor to any seal. Larger extrusion gaps will always reduce a seal’s pressure capability.

– Wear rings:

The use of wear rings always leads to larger extrusion gaps compared to a close-tolerance sliding bearing design without wear rings. The above-metal exposed portion of the wear ring and tolerances are the dominating factors for the need for larger clearances between the two sealing surfaces.

– Seal material:

Typically, a harder seal material will increase the extrusion resistance and pressure rating of a seal compared to a softer seal material. The typical hardness range for dynamic elastomeric hydraulic seals is 85-95 Shore A (similar to car tires). AHPSeals offers a variety of high-performance sealing materials in different hardness to meet the most challenging high-pressure sealing applications.

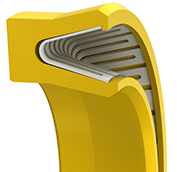

– Back-up rings:

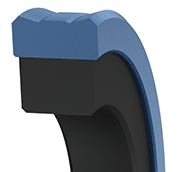

The proper design of a seal with a back-up ring will increase the pressure rating of a seal as long as the back-up ring is made of material with a higher modulus than the seal (typically noted as a harder material). AHPSeals offers specific rod and piston seals with integrated back-up rings to increase pressure capability.

– Temperature:

Higher operating temperatures will soften the seal and back-up ring material reducing its pressure capability. This affects most traditional seal materials when operating above 70% of their specified maximum operating temperature. Some of our high-performance sealing materials are designed to operate at 90% of their specified temperature without significant loss in hardness. Conversely, lower operating temperatures can increase the extrusion resistance of seal materials.

• Single- or Double-Acting Piston Seals…

• Single- or Double-Acting Piston Seals

Single- or Double-Acting Piston Seals

– Single-acting or Uni-directional – capable of sealing dynamic pressure from one side

– Double-acting or Bi-directional – capable of sealing dynamic pressure from both sides

• Lip vs. Squeeze Seals…

• Lip vs. Squeeze Seals

Lip vs. Squeeze Seals

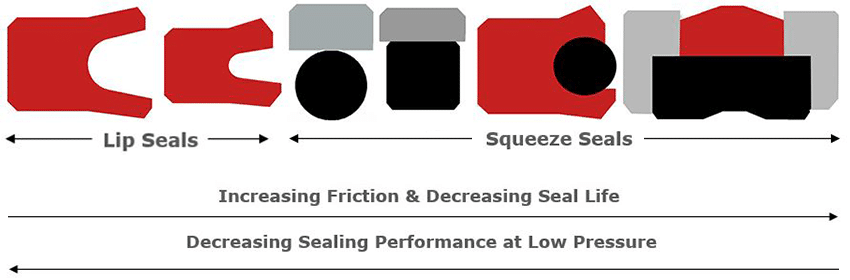

The basic design of a piston seal significantly affects the overall function of the seal, especially at low pressures. One of the most challenging applications is linear dynamic sealing at low pressure while providing low breakaway and running friction. AHPSeals provides a series of low-friction piston seals for these challenging applications.

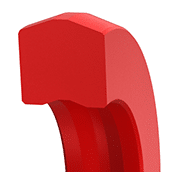

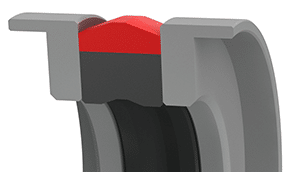

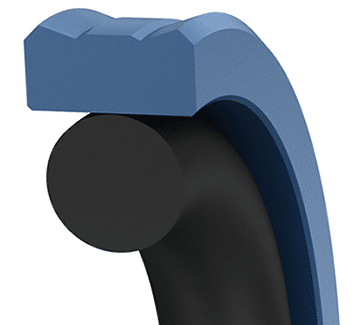

– Lip Seals are without any energizing rubber elements. Therefore, they provide a more flexible dynamic seal lip and are generally characterized by lower friction, resulting in reduced wear, longer seal life and moderate low-pressure sealing capabilities.

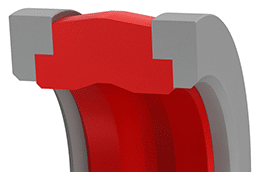

– Squeeze Seals typically incorporate an energizing rubber element and are generally characterized by high friction, high wear and good low-pressure sealing. Squeeze type seals with a PTFE cap are characterized as low friction seals under pressure. To avoid a pressure trap between two seals and potential seal failure, do not use squeeze seals for back-to-back bi-directional piston sealing applications.

• Seal Lip Geometry…

• Seal Lip Geometry

Seal Lip Geometry

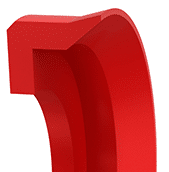

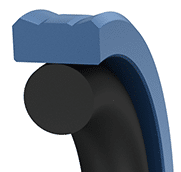

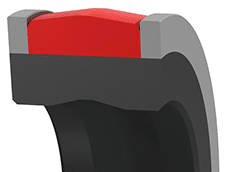

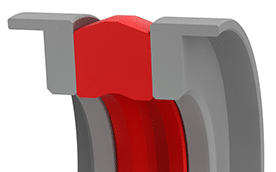

– Beveled seal lip, or chamfered seal lip, is the most aggressive seal lip design. Most of our piston seals feature this lip design as it provides the best fluid film-breaking ability, which provides the best sealing performance. Sealing lips for all AHPSeals’ piston seals are precision machined for a sharp sealing edge that cannot be achieved by a net-molding process (Fig.3).

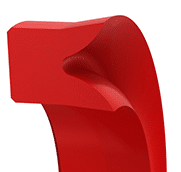

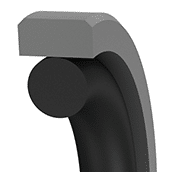

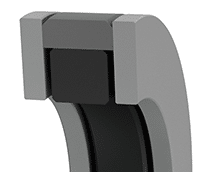

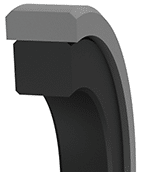

– Knife-edge and straight seal lip designs offer good scraping properties but reduced sealing performance and are used for sealing applications with high fluid contamination (Fig.4 and 5).

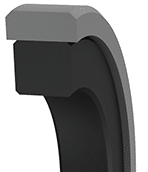

– Rounded seal lip is the least aggressive sealing lip and is typically used in pneumatic applications to maintain a microscopically thin oil or grease film on the bore to keep the piston bearing and seal lubricated (Fig. 6).

• Non-symmetrical Piston Seal Design…

• Non-symmetrical Piston Seal Design

Non-symmetrical Piston Seal Design – Features and Benefits:

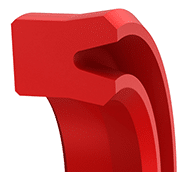

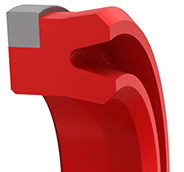

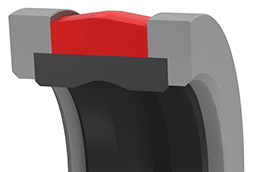

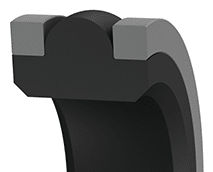

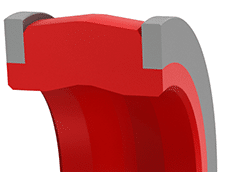

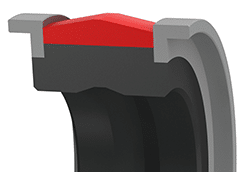

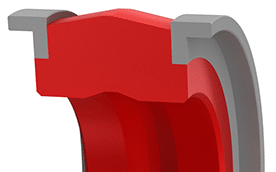

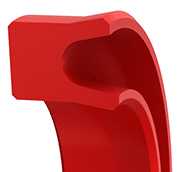

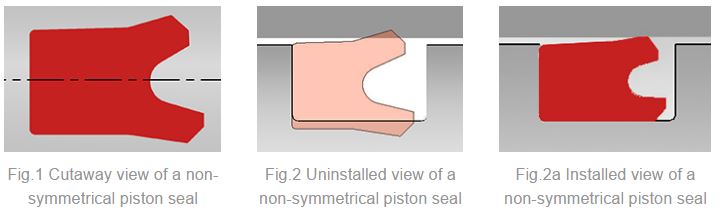

– Non-symmetrical piston seals are seals where the shape of the outside diameter lip differs from the inside diameter (see Fig.1, outside lip shorter than inside lip).

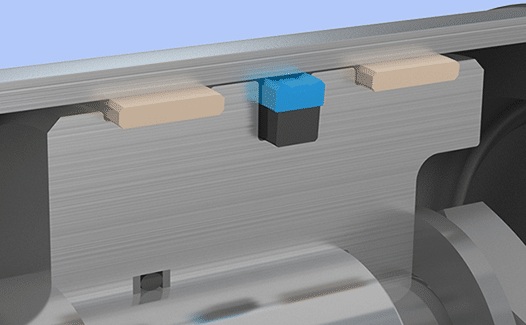

– Non-symmetrical piston seals provided by AHPSeals are not centered in the piston groove (Fig.2) and provide sealing contact with the piston across the entire surface of the static inside seal diameter (Fig. 2a) for improved static and low pressure sealing.

– Non-symmetrical piston seals are more stable and provide better sealing performance than symmetrical seals like U-cups or polypak type seals do.

Application-specific and proprietary piston seal designs are available. Please contact engineering to get the best seal for your piston sealing applications.

High-Pressure Piston Seals – up to 5,000psi (350bar)

Typical Applications

Medium duty, linear, reciprocating dynamic sealing applications

Operating Range

Pressure: up to 5,000psi (350bar)*. For pressure above 3,800psi (260bar), please contact engineering for clearances. Pressure ratings can be increased by reducing clearances.

Surface Speed: up to 13ft/s (4m/s)* depending on seal type and material

Temperature: -40°F to 400°F (-40°C to 200°C)* depending on seal material

Materials: high-performance polyurethanes, PTFE, PTFE, engineered thermoplastics, NBR, Nitrile, FKM, Viton®, H-NBR, EPDM, FDA-compliant food grades, low- and high-temperature grades, including proprietary Duralast™, Duraloy™, and Permachem™ compounds.

Availability: …More Info

Uni-directional or Single-acting High-Pressure Piston Seals – capable of sealing pressure from one side

Bi-directional or Double-acting High-Pressure Piston Seals – capable of sealing pressure from both sides

Contact us to request more information or call 1-800-283-7140 for immediate answers to your questions.

Ultra-High Pressure Piston Seals – up to 10,000 psi (700bar)

Special designs up to 28,500psi* (2,000bar)

Typical Applications

Heavy duty, linear and reciprocating dynamic sealing applications. Capable of handling high pressure spikes, larger running clearances and extrusion gaps.

Operating Range

Pressure: up to 10,000psi (700bar)*. For pressures exceeding 5,000psi (350bar), please contact engineering for clearances. Pressure rating can be increased by reducing clearances.

Surface Speed: up to 5ft/s (1.5m/s)* depending on seal type and material

Temperature: -40°F to 400°F (-40°C to 200°C)* depending on seal material

Materials: high-performance polyurethanes, PTFE, PTFE, engineered thermoplastics, NBR, Nitrile, FKM, Viton®, H-NBR, EPDM, FDA-compliant food grades, low- and high-temperature grades, including proprietary Duralast™, Duraloy™, and Permachem™ compounds.

Availability: …More Info

Uni-directional or Single-acting Ultra-High Pressure Piston Seals – capable of sealing pressure from one side

Bi-directional or Double-acting Ultra-High Pressure Piston Seals – capable of sealing pressure from both sides

Contact us to request more information or call 1-800-283-7140 for immediate answers to your questions.

Long-Life Piston Seals up to 5,000psi (350bar)

Typical Applications

Linear and reciprocating dynamic sealing applications where maximum seal life is most important.

Operating Range

Pressure: up to 5,000psi (350bar)*. For pressure above 3,800psi (260bar), please contact engineering for clearances.

Surface Speed: up to 5ft/s (1.5m/s)* depending on seal type and material

Temperature: -40°F to 400°F (-40°C to 200°C) depending on seal material

Materials: high-performance polyurethanes, PTFE, PTFE, engineered thermoplastics, NBR, Nitrile, FKM, Viton®, H-NBR, EPDM, FDA-compliant food grades, low- and high-temperature grades, including proprietary Duralast™, Duraloy™, and Permachem™ compounds.

Availability: …More Info

Uni-directional or Single-acting Long-Life Piston Seals – capable of sealing pressure from one side

Contact us to request more information or call 1-800-283-7140 for immediate answers to your questions.

Low-Friction Piston Seals up to 5,000psi (350bar)

Typical Applications

Linear and reciprocating dynamic sealing applications where low-friction is most important.

Operating Range

Pressure: up to 5,000psi (350bar)*. For pressure above 3,800psi (260bar), please contact engineering for clearances.

Surface Speed: up to 33ft/s (10m/s)* depending on seal type and material

Temperature: -95°F to 400°F (-70°C to 200°C) depending on seal material

Materials: PTFE, PTFE, high-performance polyurethanes, engineered thermoplastics, NBR, Nitrile, FKM, Viton®, H-NBR, EPDM, FDA-compliant food grades, low- and high-temperature grades, including proprietary Duralast™, Duraloy™, and Permachem™ compounds.

Availability: …More Info

Uni-directional or Single-acting Low-Friction Piston Seals – capable of sealing pressure from one side

Bi-directional or Double-acting Low-Friction Piston Seals – capable of sealing pressure from both sides

Contact us to request more information or call 1-800-283-7140 for immediate answers to your questions.

Applications & Industries

AHPSeals’ seals are currently in successful service in the following industries:

- Abrasive Substance Pumps and Valves

- Adhesives Dispensing Valves and Cylinders

- Automotive Plants

- Can and Package Filling Machines

- Cement Industry

- Chemical Pumps

- Chemical Pumps and Valves

- Construction Equipment

- Cryogenic Liquid Control Components

- Domestic Goods Production

- Drilling Equipment

- Food Processing

- Government, Military and Defense

- Heavy Mobile Equipment

- Hydraulics

- Liquid Handling Swivel Joints

- Low Friction

- Marine

- Mining

- Oil-Field Exploration and Production

- Paint and Solvent Manufacture and Application

- Pharmaceutical Production

- Pharmaceuticals

- Presses

- Rubber and Plastics

- Space Exploration

- Steel Works

- Tire Production

- Vacuum Service

- Many other Applications

*Maximum values depend on seal material, seal configuration, media, temperatures, pressures, surface speed, dynamic running surface finish and working environment. Data provided are guidelines for ideal operating conditions. Seals cannot be operated at their upper pressure and speed ratings at the same time. For maximum seal life expectancy, do not operate your seal beyond 75% of any of its operating limits. Please consult engineering or call 1-800-283-7140 for advice.

American High Performance Seals assumes no obligation or liability for any advice furnished or results obtained with respect to these products. All such advice is given and accepted at the buyer’s risk.

This information, based on our experience, is offered as part of our service to customers. It is intended for use by persons having technical skill, at their own discretion and risk. We do not guarantee favorable results, and we assume no liability in connection with its use.

Any purchases resulting from information provided by American High Performance Seals, Inc., including proposals, recommendations and quotes, are subject to “AHPSEALS TERMS AND CONDITIONS OF SALE.”