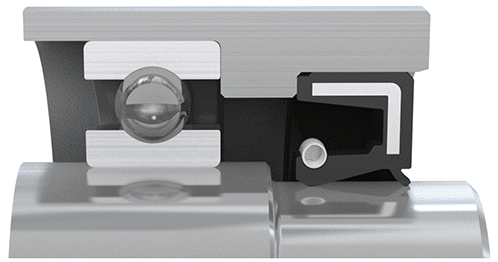

Rotary Seals

Oil Seals, Grease Seals, Bearing Seals

Rotary Shaft Seals, Radial Lip Seal and Rotary Seals for sealing dynamic, rotary motion

For oil and grease retention, no pressure or very low pressure up to 3psi (0.2bar)*

The primary function of oil seals, grease seals and bearing seals is to retain the bearing lubricant and, secondarily, to enhance the performance and life of the bearing by minimizing dirt, oil and water ingress that results in damage and premature failure of the bearing and other components. …More Info

For continuous pressures above 3psi (0.2bar), see High- and Medium-Pressure Rotary Seals.

Our Oil-, Grease- and Bearing Seals are categorized as follows:

-Standard Oil Seals, Grease and Bearing Seals

-Oil Seals, Grease Seals and Bearing Seals – Proprietary Designs

-Oil Seals, Grease Seals and Bearing Seals – Special Designs

Additional oil seal designs are available for:

High and medium pressure ; high eccentricity and misalignment, flanged, multiple seal lips for extreme dirt and mud, rotating bore sealing.

Standard Oil Seals, Grease and Bearing Seals

Typical Applications

Primarily for applications with no pressure or very low pressure up to 7psi (0.5bar) spikes*

General purpose seal for oil and grease retention for power transmission, motors, pumps, gear boxes, fans, machine tools and others.

Operating Range

Maximum Pressure: 3psi (0.2bar) continuous, 7psi (0.5bar)* max. pressure spikes depending on shaft speed

Temperature: -58 to 400°F (-50 to 200°C) depending on seal material

Shaft Surface Speed: Up to 7,000 fpm (35m/s)* depending on shaft diameter and seal material

Materials: NBR (Nitrile), FKM, Viton®, HNBR, EPDM, SIL, CR, ACM, VMQ, PTFE, low temperature and low-friction material grades.

Application-specific and proprietary seal designs are available. Please contact engineering to get the best seal for your rotary sealing applications.

Oil Seals, Grease Seals and Bearing Seals – Proprietary Designs

These seals are also available in small quantities for prototyping, repairs, seal replacements and custom sizes within 1-3 days.

Typical Applications

Primarily for applications with no pressure or very low pressure spikes up to max. 7psi (0.5bar)*

Oil and grease retention for power transmission, motors, pumps, gear boxes, fans, machine tools and others.

Operating Range

Maximum Pressure: 3psi (0.2bar) continuous, 7psi (0.5bar)* pressure spikes depending on shaft speed

Temperature: -58 to 400°F (-50 to 200°C) depending on seal material

Shaft Surface Speed: Up to 6,000 fpm (30m/s)* depending on shaft diameter and seal material

Materials: NBR (Nitrile), FKM, Viton®, EPDM, Aflas®, Silicone, Polyurethane, FDA materials HNBR, PTFE and low temperature material grades.

Availability: More Info…

Application-specific and proprietary seal designs are available. Please contact engineering to get the best seal for your rotary sealing applications.

Oil Seals, Grease Seals and Bearing Seals – Special Designs

Please contact engineering to help you in specifying the best seal for your application.

Application-specific and proprietary seal designs are available. Please contact engineering to get the best seal for your rotary sealing applications.

*Maximum values depend on seal material, seal configuration, media, temperatures, pressures, surface speed, dynamic running surface finish and working environment. Data provided are guidelines for ideal operating conditions. Seals cannot be operated at their upper pressure and speed ratings at the same time. For maximum seal life expectancy, do not operate your seal beyond 75% of any of its operating limits. Please consult engineering or call 1-800-283-7140 for advice.

American High Performance Seals assumes no obligation or liability for any advice furnished or results obtained with respect to these products. All such advice is given and accepted at the buyer’s risk.

This information, based on our experience, is offered as part of our service to customers. It is intended for use by persons having technical skill, at their own discretion and risk. We do not guarantee favorable results, and we assume no liability in connection with its use.