R2SL

Double-lip oil seal for worn shafts

Double-lip oil seal for use on worn or grooved shafts or increased runout.

Optimized seal lip design contacts the shaft at a new contact point which enables this seal to be fitted on most grooved shafts where a repair sleeve or a new shaft would be required. For increased runout or eccentricity, the seal lip length is optimized. Thermoplastic reinforcement element ensures concentric fitment and increased corrosion resistance. Secondary lip serves as both effective protection against airside contaminants and as a lube retainer. Maximum service life can be achieved by applying a suitable lubricant between the two sealing lips. Available in a wide range of elastomers and small quantities for repairs and seal replacement and can be shipped in 1 to 3 days.

| Material | Continuous Pressure | Max.Pressure Spike | Temperature | Surface Speed |

|---|---|---|---|---|

| N101 | 3psi (0.2bar) | 7psi (0.5bar) | -13 to 212°F (-25 to 100°C) | Up to 1,800 fpm (9m/s) |

| N102 | 3psi (0.2bar) | 7psi (0.5bar) | -13 to 302°F (-25 to 150°C) | Up to 2,800 fpm (14m/s) |

| V101 | 3psi (0.2bar) | 7psi (0.5bar) | -4 to 392°F (-20 to 200°C) | Up to 4,000 fpm (20m/s) |

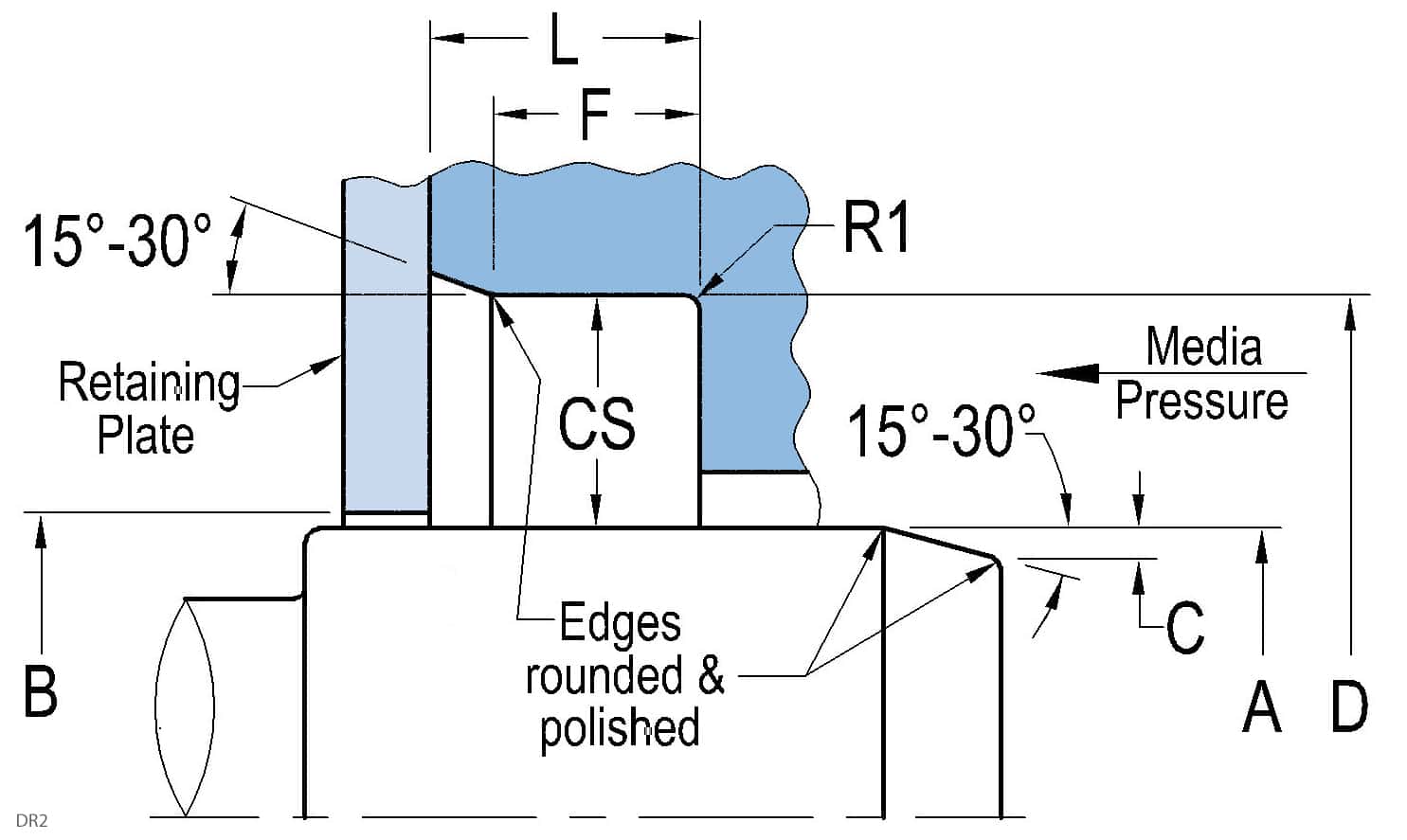

| A Shaft Diameter | CS Cross- | D Bore Diameter | B Diameter Tol. +/- 0.010 | L | F | C Chamfer | R1 Radius |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Standard Range | Functional Range | Tolerance | section | D= | Tolerance | B= | Tol. +0.010/-0 | min. | max. | |

| 0.250 - 1.499" | 0.250 - 8.000" | +/-0.003 | 3/8 | A + 0.750 | +/-.001 | A + 0.060 | 0.387 | 0.300 | 0.060 | 0.020 |

| 1.500 - 7.999" | 0.500 - 15.000" | +/-0.004 | 1/2 | A + 1.000 | +/-.0015 | A + 0.080 | 0.512 | 0.425 | 0.090 | 0.030 |

| 8.000 - 15.999" | 1.250 - 63.000" | +/-0.005 | 5/8 | A + 1.250 | +/-.002 | A + 0.080 | 0.637 | 0.530 | 0.130 | 0.030 |

| 16.000 - 30.999" | 2.500 - 63.000" | +/-0.006 | 3/4 | A + 1.500 | +/-.003 | A + 0.080 | 0.637 | 0.530 | 0.150 | 0.030 |

| 31.000 - 63.000" | consult with Ahpseals engineering | |||||||||

| *Standard cross-sections (CS) listed and non-standard sizes can be provided for any shaft size up to 63 inches. Seal retaining plat is recommended for split seals or ressures above 3psi. Surface finish: Shaft (A) plunge ground, zero lead, Ra 8-16µin Housing (D,L) Ra 32-63µin. Shaft material hardness min. C45. See Technical Info for more specific information. | ||||||||||