Rotary Seals

High-Pressure Rotary Seals & Medium-Pressure Rotary Seals

For sealing dynamic, rotary motion

Leakage control of medium to high pressure on rotary equipment is one of the most challenging sealing applications. …More Info Under higher pressure, the sliding contact area between the seal lip and the shaft will generate much higher friction, heat and wear of the seal lip than under zero system pressure, causing premature or catastrophic seal failure in a very short period of time when using rotary seals not specifically designed for higher pressures. Special attention must be paid to the selection of a suitable seal design and appropriate seal material.

Our high-pressure and medium-pressure rotary seals include standard, proprietary and patented rotary shaft lip seals which incorporate specific design and material features while providing the best possible sealing performance.

These design features can lower:

- Parasitic friction

- Heat build up

- Seal and shaft wear

- Torque generation

- Required power consumption

Please contact one of our experienced seal engineers to select the best seal for your application.

Our Standard High- and Medium-Pressure Rotary Seals are categorized as follows:

Medium-Pressure Rotary Seals

– up to 150psi (10.3bar)*; PV-Rating 0.9 to 2.0

– up to 200psi (14bar)*; PV-Rating 1.4 to 5.0

– up to 500psi (35bar)*; PV-Rating 5.0 to 9.0

High-Pressure Rotary Seals

– up to 3,500psi (240bar)*; PV-Rating 7.0 to 9.0

– up to 10,000psi (350bar)*; PV-Rating 6.0 to 10.0

– Special seal designs up to 20,000psi (1,400bar)* contact engineering,

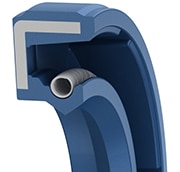

Medium-Pressure Rotary Seals – up to 150psi; PV-Rating 0.9 to 2.0

Typical Applications

-Sealing pressure from one side

-Pumps, motors, compressors, machine tools, brakes, clutches, mixers and others.

Operating Range

Pressure: up to 60psi (4.1bar) continuous* depending on shaft speed; up to 150psi (10.3bar)* max. pressure spikes. For pressures exceeding 40psi (2.7bar), please contact engineering.

Surface Speed: up to 2,700fpm (13.5m/s)* depending on pressure

Temperature: -58 to 400°F (-50 to 200°C)* depending on material

PV-Rating: 0.9 to 2.0 depending on seal design and material

Seals can not be operated at their upper pressure and speed ratings at the same time.

Materials: Low-friction NBR/Nitrile and FKM/Viton®, HNBR, EPDM, SIL, CR, ACM, VMQ, low- and high-temperature and FDA-compliant grades.

Application-specific and proprietary seal designs are available. Please contact engineering to get the best seal for your rotary sealing applications.

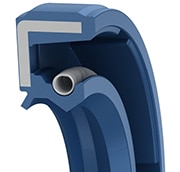

Medium-Pressure Rotary Seals – up to 200psi; PV-Rating 1.4 to 5.0

Typical Applications

-Sealing pressure from one side

-Pumps, motors, compressors, machine tools, brakes, clutches, mixers, dispensing heads and others.

Operating Range

Pressure: up to 110psi (7.6bar) continuous* depending on shaft speed, up to 200psi (14bar)*max. pressure spikes. For pressures exceeding 60psi (4bar), please contact engineering.

Surface Speed: up to 6,000fpm (30m/s)* depending on pressure

Temperature: -58 to 400°F (-50 to 200°C)* depending on seal material

PV-Rating: 1.4 to 5.0 depending on seal design and material

Seals can not be operated at their upper pressure and speed ratings at the same time.

Materials: NBR (Nitrile), FKM, Viton®, HNBR, EPDM, SIL, CR, ACM, VMQ, PTFE, low-temperature material grades and FDA-compliant grades.

Application-specific and proprietary seal designs are available. Please contact engineering to get the best seal for your rotary sealing applications.

Medium-Pressure Rotary Seals – up to 500psi; PV-Rating 5.0 to 9.0

Typical Applications

– Lower torque and power consumption, sealing differential pressure from one side

– Pumps, motors, compressors, machine tools, brakes, clutches, mixers and others.

Operating Range

Pressure: up to 150psi (10.3bar) continuous* depending on shaft speed, up to 500psi (35bar)* max. pressure spikes. For pressures exceeding 80psi (5.5bar), please contact engineering.

Surface Speed: up to 7,000fpm (35m/s)* depending on pressure

Temperature: -58 to 400°F (-50 to 200°C)* depending on seal material

PV-Rating: 5.0 to 9.0 depending on seal design and material

Seals can not be operated at their upper pressure and speed ratings at the same time.

Materials: NBR (Nitrile), FKM, Viton®, HNBR, EPDM, PTFE, low-temperature material grades FDA-compliant grades and proprietary materials.

Application-specific and proprietary seal designs are available. Please contact engineering to get the best seal for your rotary sealing applications.

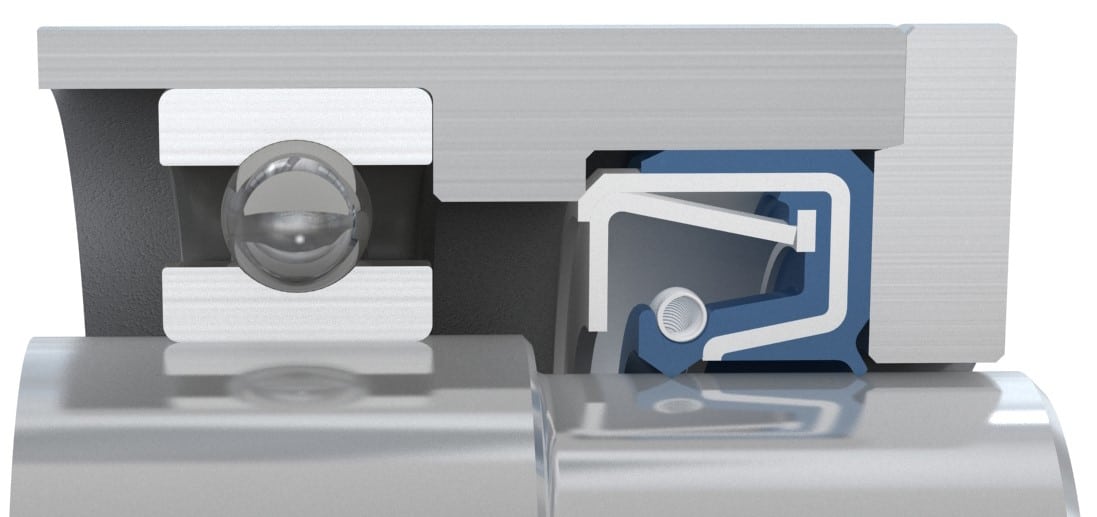

High-Pressure Rotary Seals – up to 3,500psi max. – PV-Rating: 7.0 to 9.0

Typical Applications

Pumps, motors, rotary couplings, brakes, winches and draw-works, mixers, drilling equipment, downhole tools, swivels and others.

Operating Range

Pressure: up to 3,500psi (240bar)* special designs up to 10,000psi (700bar)* at low surface speeds. For pressures exceeding 3,000psi (210bar), please contact engineering

Surface Speed: up to 1,200fpm (6m/s)* depending on pressure

Temperature: -40 to 400°F (-40 to 200°C)* depending on material

PV-Rating: 7.0 to 9.0 depending on seal design and material

Seals can not be operated at their upper pressure and speed ratings at the same time.

Materials: PTFE composite and proprietary materials

Availability: More Info…

Uni-directional High-Pressure Rotary Seals – capable of sealing pressure from one side

Application-specific and proprietary seal designs are available. Please contact engineering to get the best seal for your rotary sealing applications.

Bi-directional High-Pressure Rotary Seals- capable of sealing pressure from both sides

Application-specific and proprietary seal designs are available. Please contact engineering to get the best seal for your rotary sealing applications.

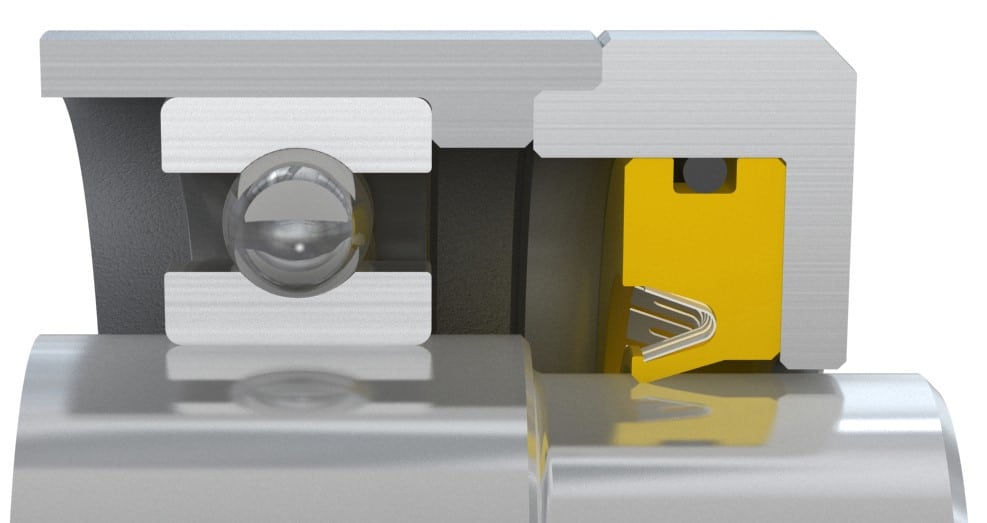

High-Pressure Rotary Seals – up to 10,000psi – PV-Rating: 6.0 to 10.0

Typical Applications

Swivels, rotary manifolds, slew rings, positioning equipment, downhole tools and others.

Operating Range

Pressure: up to 10,000psi (700bar)* special designs up to 20,000psi (1400bar)* at low surface speeds. For pressures exceeding 3,000psi (210bar), please contact engineering.

Surface Speed: up to 400fpm (2m/s)* depending on pressure

Temperature: -58 to 400°F (-50 to 200°C)* depending on material

PV-Rating: 6.0 to 10.0 depending on seal design and material

Seals can not be operated at their upper pressure and speed ratings at the same time.

Materials: PTFE composite and proprietary materials

Availability: More Info…

High-Pressure Rotary Seals – 5,000 psi max.

Application-specific and proprietary seal designs are available. Please contact engineering to get the best seal for your rotary sealing applications.

High-Pressure Rotary Seals – 10,000 psi max.

Application-specific and proprietary seal designs are available. Please contact engineering to get the best seal for your rotary sealing applications.

*Maximum values depend on seal material, seal configuration, media, temperatures, pressures, surface speed, dynamic running surface finish and working environment. Data provided are guidelines for ideal operating conditions. Seals cannot be operated at their upper pressure and speed ratings at the same time. For maximum seal life expectancy, do not operate your seal beyond 75% of any of its operating limits. Please consult engineering or call 1-800-283-7140 for advice.

American High Performance Seals assumes no obligation or liability for any advice furnished or results obtained with respect to these products. All such advice is given and accepted at the buyer’s risk.

This information, based on our experience, is offered as part of our service to customers. It is intended for use by persons having technical skill, at their own discretion and risk. We do not guarantee favorable results, and we assume no liability in connection with its use.