Hydraulic & Fluid Seals

Wipers

For dirt and contaminants exclusion

The primary function of a wiper is to keep contaminants such as dirt, dust and moisture from entering the fluid power system.

Contaminants can cause significant damage to the rod, cylinder wall, seals, valves and other components. One of the primary causes of premature seal and component failure in a fluid power system is contamination. It should be noted that rod seal failure is normally a swift result of wiper failure. Particular attention should be drawn to the selection of the wiper, and the following should be taken into consideration:

Wiper Design Considerations:

• Groove Geometry…

• Groove Geometry

Groove Geometry

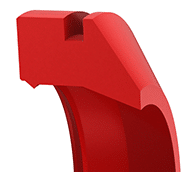

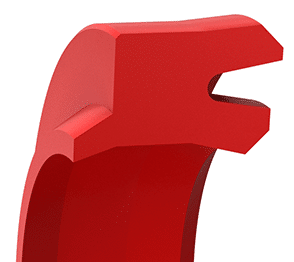

– Snap-in design (Fig.1)

Generally the least expensive wiper, it is more costly to machine the groove; however, this style provides the best long-term wiping performance.

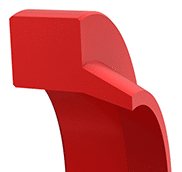

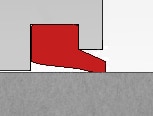

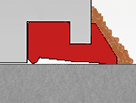

– Press-in design (Fig.2)

The wiper designed for press-in installation is typically more costly, while the machining of the gland is less costly.

Fig.1 Snap-in design

Fig.2 Press-in design

• Lip Geometry…

• Lip Geometry

Lip Geometry

When the rod extends past the rod seal, a thin film of oil remains on the rod, trapped in microscopic surface imperfections. The thickness of the oil film depends upon the surface finish, rod seal and surface speed of the rod. During the return stroke, this thin film can be removed by an aggressive wiper lip, resulting in system leakage.

It is important to properly pair the wiper and rod seal. If the wiper and the rod seal are not matched, leakage and premature failure can occur. An aggressive wiper lip requires an aggressive rod seal lip design or a redundant High-Performance Rod Sealing System

Further consideration is the lip geometry, which we distinguish as:

– Single lip, straight wiper lip design (Fig.3) is the most aggressive. It offers the best scraping and dirt removal performance and is recommended for most sealing applications with high contamination

– Single beveled wiper lip or chamfered wiper lip (Fig.4) is less aggressive. The beveled lip allows the microscopically thin oil film on the rod to be retracted back into the system while providing adequate dirt exclusion in less contaminated environments.

– Single rounded seal lip is the least aggressive sealing lip and is typically used in pneumatic applications to maintain a microscopically thin oil or grease film on the rod to keep the piston bearing and seal lubricated (Fig. 5).

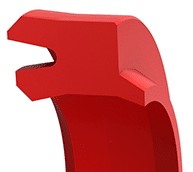

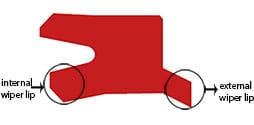

– Double or redundant wiper lips (Fig.6) are one of the most effective ways to improve a system’s sealing performance. This wiper design must be paired with one of our Long-Life Rod Seals to provide for the driest long-life rod sealing available. It eliminates the release of built-up fluid pressure (pressure trap) between the wiper and the rod seal, also known as “burping,” by releasing built-up fluid pressure back past the rod seal and into the system.

Wiper with single lip

Fig.3 straight wiper lip

Fig.4 beveled wiper lip

Fig.5 rounded wiper lip

Fig.6 Wiper A15 with double or redundant sealing lips

• Working Environment…

• Working Environment

Working Environment

In applications where the equipment is exposed to heavy dirt, mud and moisture, all-weather conditions or where the rod of the cylinder is vertical or upward orientated, it is possible for moisture or other contaminants to get past the wiper, leading to corrosion and damage of components and seals. For these applications, we offer Highly-contaminated Environment Wipers (Fig.7, Fig.8) with specific design features incorporating an accurate closure between the housing and the wiper outside diameter (OD) to keep contamination out on both the dynamic OD and static OD surface.

Fig.7 Wiper A15

Fig.8 Wiper W51

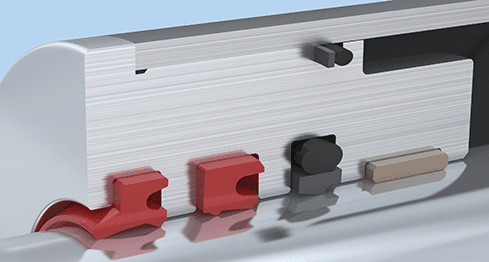

Our Wipers are classified as follows:

– Highly-Contaminated Environment Wipers & Scrapers

– Dust and Particle Exclusion Wipers

– Dry Rod Operation Wipers

– Low-Friction System Wipers

Application-specific and proprietary wiper and seal designs are available. Please contact engineering to get the best seal for your rod sealing applications

Highly Contaminated Environment Wipers & Scrapers

Typical Application

For heavy dirt, mud and moisture exclusion or equipment that is exposed to all-weather conditions, including applications with a vertical or upward orientated rod of the cylinder.

Operating Range

Surface Speed: up to 13ft/s (4m/s)* depending on wiper type and material

Temperature: -40°F to 400°F (-40°C to 200°C)* depending on seal material

Materials: high-performance polyurethanes, PTFE, PTFE, engineered thermoplastics, NBR, Nitrile, FKM, Viton®, H-NBR, EPDM, FDA-compliant food grades, low- and high-temperature grades, including proprietary Duralast™, Duraloy™, and Permachem™ compounds.

Availability: More Info…

Snap-in design wipers

Press-in design wipers

Contact us to request more information or call 1-800-283-7140 for immediate answers to your questions.

Dust and Particle Exclusion Wipers

Typical Application

Recommended for applications operating in a fairly clean environment with some exposure to dust and particles.

Operating Range

Surface Speed: up to 13ft/s (4m/s)* depending on wiper type and material

Temperature: -40°F to 400°F (-40°C to 200°C)* depending on seal material

Materials: high-performance polyurethanes, PTFE, PTFE, engineered thermoplastics, NBR, Nitrile, FKM, Viton®, H-NBR, EPDM, low- and high-temperature grades, including proprietary Duralast™, Duraloy™, and Permachem™ compounds.

Availability: More Info…

roll-over pop-up comments and other features

Snap-in design wipers

Press-in design wipers

Contact us to request more information or call 1-800-283-7140 for immediate answers to your questions.

Dry Rod Operation Wipers

Typical Application

Recommended for applications where achieving the driest rod is most important.

Operating Range

Surface Speed: up to 13ft/s (4m/s)* depending on wiper type and material

Temperature: -40°F to 400°F (-40°C to 200°C)* depending on seal material

Materials: high-performance polyurethanes, PTFE, PTFE, engineered thermoplastics, NBR, Nitrile, FKM, Viton®, H-NBR, EPDM, FDA-compliant food grades, low- and high-temperature grades, including proprietary Duralast™, Duraloy™, and Permachem™ compounds.

Availability: More Info…

Snap-in design wipers

Press-in design wipers

Contact us to request more information or call 1-800-283-7140 for immediate answers to your questions.

Low Friction System Wipers

Typical Application

Recommended for applications where achieving low friction is most important.

Operating Range

Surface Speed: up to 13ft/s (4m/s)* depending on wiper type and material

Temperature: -40°F to 400°F (-40°C to 200°C)* depending on seal material

Materials: high-performance polyurethanes, PTFE, PTFE, engineered thermoplastics, NBR, Nitrile, FKM, Viton®, H-NBR, EPDM, FDA-compliant food grades, low- and high-temperature grades, including proprietary Duralast™, Duraloy™, and Permachem™ compounds.

Availability: More Info…

Snap-in design wipers

Contact us to request more information or call 1-800-283-7140 for immediate answers to your questions.

Applications & Industries

AHPSeals’ wipers are currently in successful service in the following industries:

- Abrasive Substance Pumps and Valves

- Adhesives Dispensing Valves and Cylinders

- Automotive Plants

- Can and Package Filling Machines

- Cement Industry

- Chemical Pumps

- Chemical Pumps and Valves

- Construction Equipment

- Cryogenic Liquid Control Components

- Drilling Equipment

- Food Processing

- Government, Military and Defense

- Heavy Mobile Equipment

- Hydraulics

- Liquid Handling Swivel Joints

- Low Friction

- Marine

- Mining

- Oil-Field Exploration and Production

- Paint and Solvent Manufacture and Application

- Pharmaceuticals

- Presses

- Rubber and Plastics

- Space Exploration

- Steel Works

- Tire Production

- Vacuum Service

- Many other applications

*Maximum values depend on seal material, seal configuration, media, temperatures, pressures, surface speed, dynamic running surface finish and working environment. Data provided are guidelines for ideal operating conditions. Seals cannot be operated at their upper pressure and speed ratings at the same time. For maximum seal life expectancy, do not operate your seal beyond 75% of any of its operating limits. Please consult engineering or call 1-800-283-7140 for advice.

American High Performance Seals assumes no obligation or liability for any advice furnished, or results obtained with respect to these products. All such advice is given and accepted at the buyer’s risk.

This information, based on our experience, is offered as part of our service to customers. It is intended for use by persons having technical skill, at their own discretion and risk. We do not guarantee favorable results, and we assume no liability in connection with its use

Any purchases resulting from information provided by American High Performance Seals, Inc., including proposals, recommendations and quotes, are subject to “AHPSEALS TERMS AND CONDITIONS OF SALE.”