ASHP5

Supreme medium-pressure double-lip oil seal

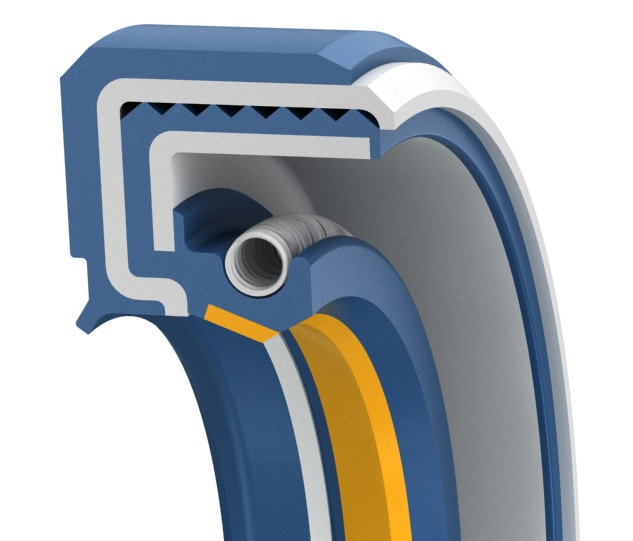

Medium-pressure double-lip oil seal with integrated seal lip support, and proprietary blends of PTFE bonded onto the dynamic sealing lip.

Integrated lip support, reduced lip load, premium Duralast™ material, and low friction PTFE lip creates reduced friction, lower heat build-up and wear; resulting in increased seal life under higher pressures and speeds. This allows the seal to handle higher operating pressure. The rubber-covered OD of the seal creates a tight seal with the housing bore, and the press-in fitment design accommodates housings with short axial space requirements. The secondary lip serves as effective protection against airside contaminants and as a lube retainer. Maximum service life can be achieved by applying a suitable lubricant between the two sealing lips.

| Material | Continuous Pressure | Max. Pressure Spike | Temperature | Surface Speed | Dry-run | PV-Rating |

|---|---|---|---|---|---|---|

| Fluoroelastomer (FKM), Viton®/PTFE | 150psi (10.3bar) | 300psi (20.7bar) | -40 to 400°F (-40 to 200°C) | Up to 5,000 fpm (25m/s) | YES | 7 |

| NBR/PTFE | 150psi (10.3bar) | 300psi (20.7bar) | -40 to 230°F (-40 to 110°C) | Up to 2,500 fpm (12.5m/s) | YES | 5 |

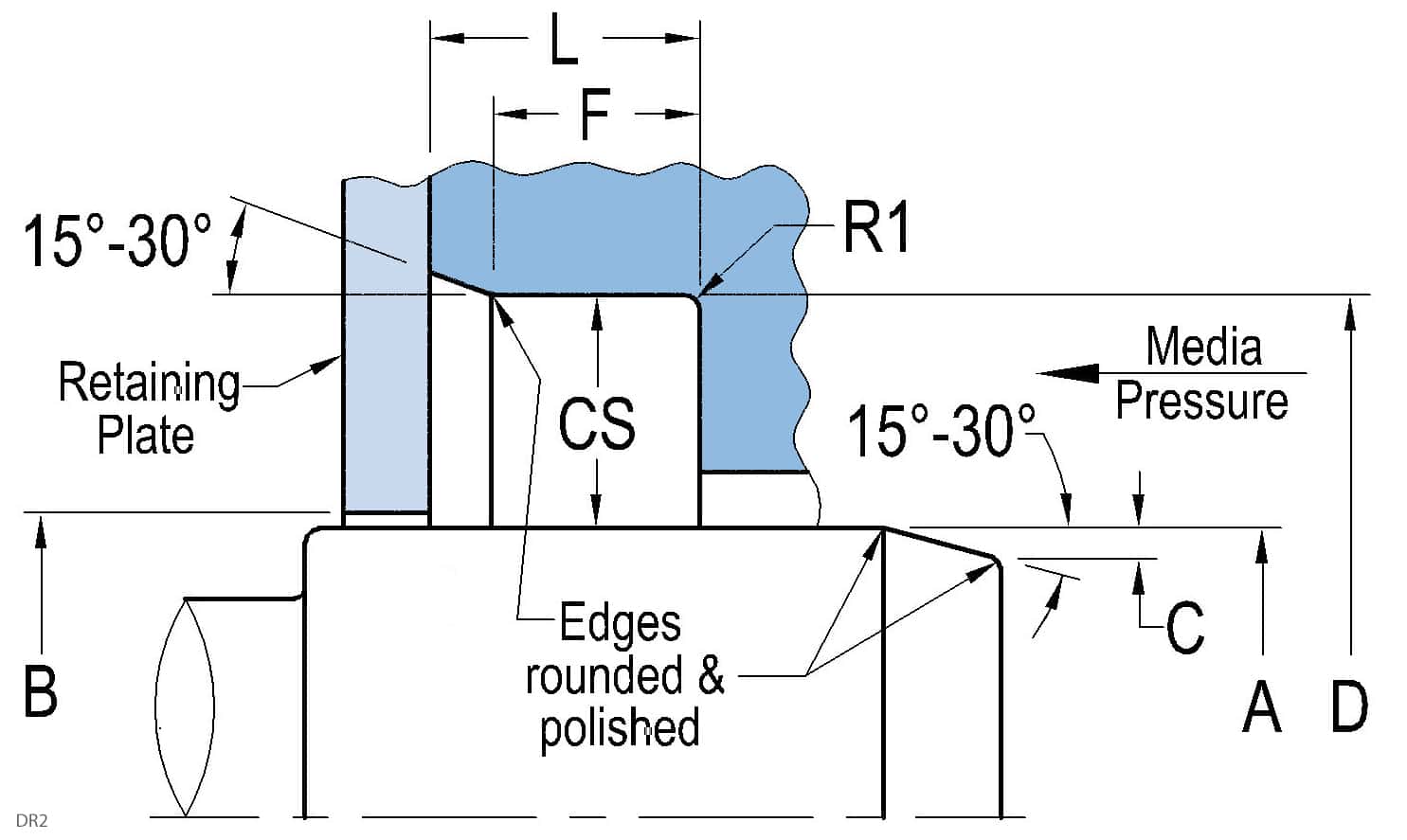

| A Shaft Diameter | CS Cross-section | D Bore Diameter | B Diameter Tol. +/- 0.010 | L | F | C Chamfer | R1 Radius |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Standard Range | Functional Range | Tolerance | D= | Tolerance | B= | Tol. +0.010/-0 | min. | max. | ||

| 0.750-2.999" | 0.750 - 31.000" | +/-0.003 | 7/16 | A + 0.875 | +/-.001 | A + 0.100 | 0.450 | 0.383 | 0.040 | 0.020 |

| 3.000 - 5.999" | 0.750 - 31.000" | +/-0.004 | 1/2 | A + 1.000 | +/-.0015 | A + 0.200 | 0.512 | 0.425 | 0.090 | 0.030 |

| 6.000 - 13.999" | 1.000 - 31.000" | +/-0.005 | 5/8 | A + 1.250 | +/-.002 | A + 0.200 | 0.637 | 0.530 | 0.130 | 0.030 |

| 14.000 - 30.999" | 2.000 - 31.000" | +/-0.006 | 3/4 | A + 1.500 | +/-.003 | A + 0.220 | 0.637 | 0.530 | 0.150 | 0.030 |

| 31.000 - 63.000" | consult with AHPSeals engineering | |||||||||

| *Standard cross-sections (CS) listed and non-standard sizes can be provided for any shaft size up to 63 inches. Seal retaining plate for pressures above 7 psi recommended. Surface finish: Shaft (A) plunge ground, zero lead, Ra 8-16µin for rubber seal lip, Ra 6-12µin for PTFE seal lip. Housing (D,L) Ra 32-63µin, shaft material hardness 55-65RC. See Technical Info for more specific information. | ||||||||||