AS

Spring-loaded double-lip oil seal

Premium spring-loaded double-lip oil seal with integrated steel reinforcement element. Used for oil or grease retention.

The optimized seal lip design uses a garter spring to maintain a constant radial lip load, thus ensuring optimum sealability. The rubber covered OD press fits to create a positive seal with the housing bore. The rubber OD also provides optimal compensation for housings of different thermal expansion, reducing possibility of fretting corrosion in soft alloy or plastic housings, and accommodating higher surface roughness of the housing bore. The secondary lip serves both as an effective protection against light airside contaminants and as a lube retainer. Maximum service life can be achieved by applying a suitable lubricant between the two sealing lips. For medium and heavy duty dirt exclusion see ADG or AJ multy-lip design oil/grease seals.

| Material | Continuous Pressure | Max. Pressure Spike | Temperature | Surface Speed |

|---|---|---|---|---|

| Duralast 8838-LF | 3psi (0.2bar) | 7psi (0.5bar) | -4 to 392°F (-20 to 200°C) | Up to 5,000 fpm (25m/s) |

| Duralast 5117-LF | 3psi (0.2bar) | 7psi (0.5bar) | -13 to 212°F (-25 to 100°C) | Up to 1,800 fpm (9m/s) |

| Fluoroelastomer (FKM),Viton® | 3psi (0.2bar) | 7psi (0.5bar) | -4 to 392°F (-20 to 200°C) | Up to 4,000 fpm (20m/s) |

| Nitrile (NBR) | 3psi (0.2bar) | 7psi (0.5bar) | -13 to 212°F (-25 to 100°C) | Up to 1,600 fpm (8m/s) |

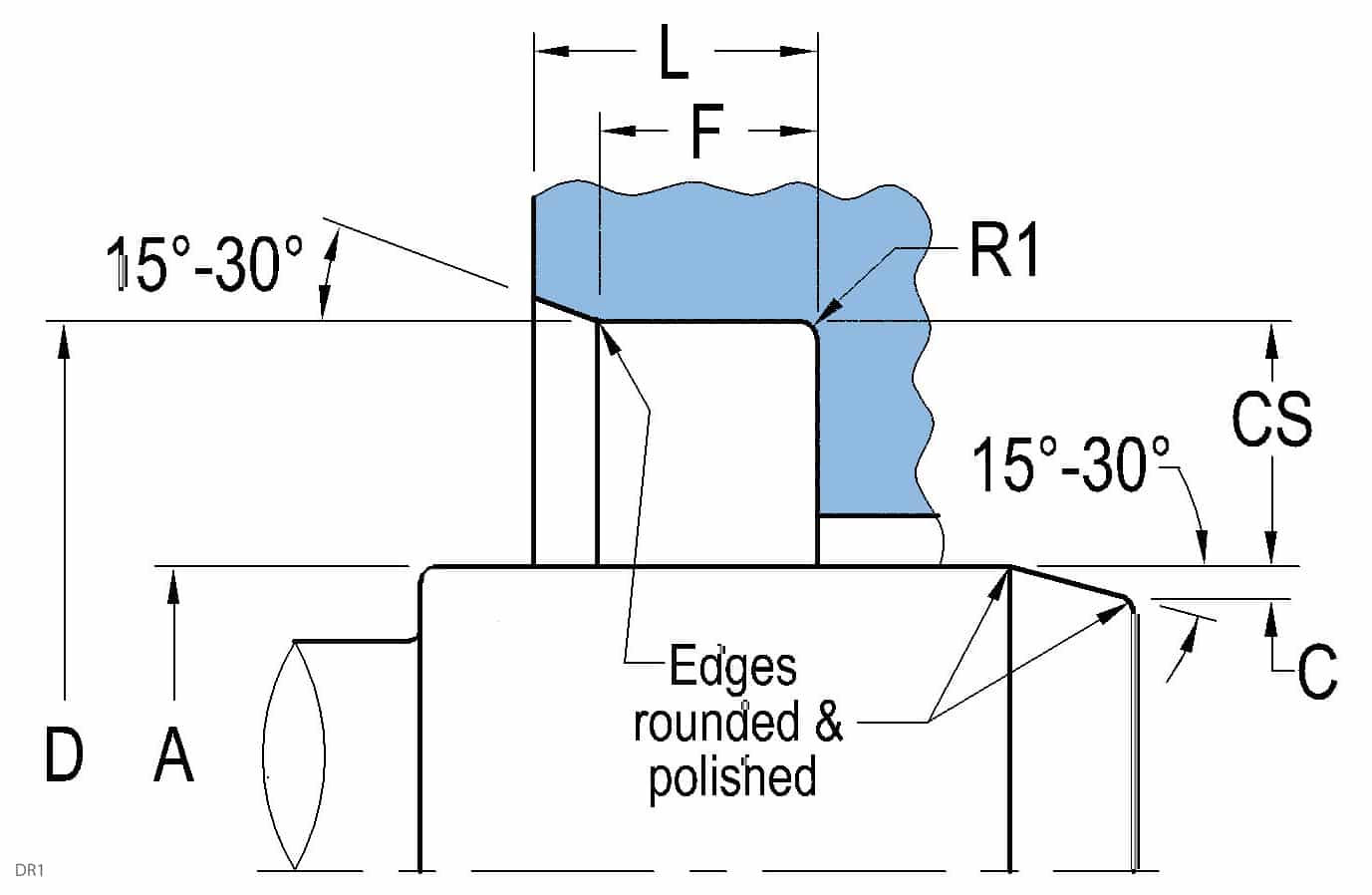

| A Shaft Diameter | CS Cross-section | D Bore Diameter | L | F | C Chamfer | R1 Radius |

|||

|---|---|---|---|---|---|---|---|---|---|

| Standard Range | Functional Range | Tolerance | * | D= | Tolerance | Tol. +0.010/-0 | min. | max. | |

| 0.200-0.599" | 0.200 - 5.000" | +/-0.003 | 3/16 | A + 0.375 | +/-.001 | 0.262 | 0.210 | 0.040 | 0.020 |

| 0.600-1.299" | 0.200 - 6.000" | +/-0.003 | 1/4 | A + 0.500 | +/-.001 | 0.262 | 0.210 | 0.050 | 0.020 |

| 1.300 - 2.299" | 0.200 - 7.000" | +/-0.003 | 5/16 | A + 0.625 | +/-.001 | 0.325 | 0.265 | 0.050 | 0.020 |

| 2.300 - 3.299" | 0.250 - 10.000" | +/-0.003 | 3/8 | A + 0.750 | +/-.001 | 0.387 | 0.300 | 0.060 | 0.020 |

| 3.300 - 7.999" | 0.500 - 15.000" | +/-0.004 | 1/2 | A + 1.000 | +/-.0015 | 0.512 | 0.425 | 0.090 | 0.030 |

| 8.000 - 15.999" | 1.000 - 63.000" | +/-0.005 | 3/4 | A + 1.500 | +/-.002 | 0.637 | 0.530 | 0.130 | 0.030 |

| 16.000 - 30.999" | 1.000 - 63.000" | +/-0.006 | 3/4 | A + 1.500 | +/-.003 | 0.637 | 0.530 | 0.150 | 0.030 |

| 31.000 - 63.000" | consult with Ahpseals engineering | ||||||||

| *Standard cross-sections (CS) listed and non-standard sizes can be provided for any shaft size up to 63 inches. Surface finish: Shaft (A) plunge ground, zero lead, Ra 8-16µin - Housing (D,L) Ra 32-63µin. Shaft material hardness min. RC45. See Technical Info for more specific information. |

|||||||||