K8B

Premium High-Pressure Bi-Directional Hydraulic Piston Seal

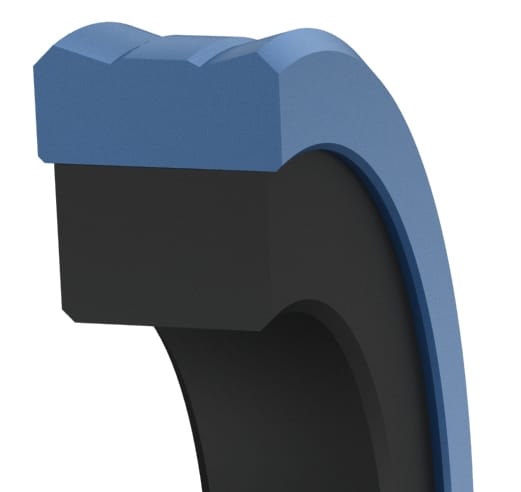

Rectangular energized cap seal design for high-pressure piston sealing applications. Rectangular energizer ensures a stable, positive seal and provides continuous contact along the sealing surface. The specially designed hard wearing cap is easier to install than PTFE cap seals and provides high extrusion resistance. Further, the design provides a fluid reservoir between the two beveled sealing lips which retains system fluid, resulting in reduced running and breakaway friction. Beveled sealing lips for maximum fluid sealing ability protect against extrusion during pressure spikes. The small axial seal height reduces piston height, weight and cost. ISO 7425-1 and many standard and custom sizes available.

| Material | Operating Pressure up to | Maximum Pressure up to | Temperature | Surface Speed up to | Fluid, Media Compatability |

|---|---|---|---|---|---|

| Duralast 4203 | 3,800psi (260bar) | 5,000psi (350bar) | -22°F to 260°F (-30°C to 125°C) | 1.6ft/s (0.5m/s) | mineral oil-based fluids, fire-resistant water-based hydraulic fluids including HFA and HFB, sea water, biodegradable fluids, vegetable oils, bio-diesels, and most modern hydraulic fluids |

| Duralast 4403 | 5,000psi (350bar) | 8,000psi (520bar) | -22°F to 260°F (-30°C to 125°C) | 1.6ft/s (0.5m/s) | same as Duralast 4203 |

| Additional standard materials available: High-performance polyurethanes, low- and high-temperature, FDA-compliant seal material grades, engineered thermoplastics, Hytrel®, NBR (Nitrile), FKM, Viton®, HNBR, EPDM, Aflas®, Silicone, and proprietary specialized Duralast™, Duraloy™, and Permachem™ materials. | |||||

| Important Note: Maximum values above depend on extrusion gap, clearances, seal material, media, temperatures, pressures, surface speed, dynamic running surface finish and working environment. Seals cannot be operated at their upper ratings at the same time. Pressure ratings can be increased by reducing clearances. For pressure above specified operating pressure, please contact engineering@ahpseals.com | |||||

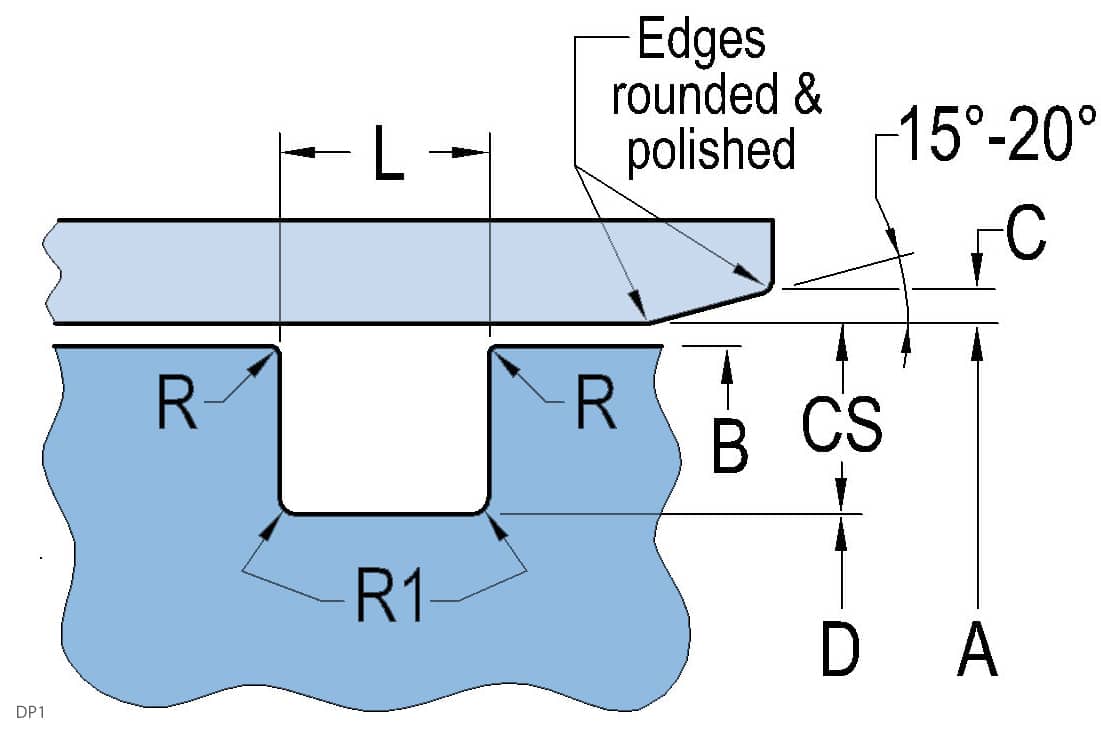

| A Bore Diameter | CS Cross-Section | D Groove Diameter | B* Piston Diameter | Tolerance | L Groove Width | C | R1 | R | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Standard Range | Functional Range | Tolerance | D= | B= | D,B | Tol.+0.008/-0 | min. | max. | max. | |

| 0.312 - 0.564" | 0.300 - 0.599" | +0.001/-0 | 0.097 | A - 0.194 | A - 0.024 | +.000/-.001 | 0.087 | 0.045 | 0.015 | 0.006 |

| 0.565 - 1.499" | 0.550 - 1.599" | +0.002/-0 | 0.148 | A - 0.296 | A - 0.024 | +.000/-.002 | 0.126 | 0.050 | 0.025 | 0.008 |

| 1.500 - 3.124" | 0.550 - 12.000" | +0.003/-0 | 0.217 | A - 0.434 | A - 0.027 | +.000/-.003 | 0.165 | 0.070 | 0.025 | 0.008 |

| 3.125 - 5.249" | 1.500 - 18.500" | +0.003/-0 | 0.305 | A - 0.610 | A - 0.029 | +.000/-.003 | 0.248 | 0.100 | 0.035 | 0.008 |

| 5.250 - 12.499" | 3.000 - 26.500" | +0.004/-0 | 0.414 | A - 0.828 | A - 0.030 | +.000/-.004 | 0.320 | 0.130 | 0.035 | 0.008 |

| 12.500 - 26.599" | 5.000 - 26.500" | +0.005/-0 | 0.483 | A - 0.966 | A - 0.034 | +.000/-.005 | 0.320 | 0.130 | 0.035 | 0.008 |

| 26.600 - 40.124" | 10.000 - 50.000" | +0.007/-0 | 0.552 | A - 1.102 | A - 0.045 | +.000/-.007 | 0.375 | 0.150 | 0.040 | 0.012 |

| 40.125 - 72.500" | 20.000 - 72.500" | +0.009/-0 | 0.748 | A - 1.496 | A - 0.050 | +.000/-.009 | 0.543 | 0.170 | 0.050 | 0.012 |

| > 72.500" | consult with Ahpseals engineering | |||||||||

| * Based on using wear rings. For pressure above 3,800psi or diameter 26,500", please contact engineering for clearances. Surface finish: rod (A) Ra 4-12µin – Static (D,L) Ra max. 32µin. See Technical Info for more specific information. | ||||||||||