High Pressure Seals (PV) FAQ

What is PV?

PV is simply Pressure x Velocity and is generally expressed in psi x fpm.

How is it calculated?

Pressure (psi) x Surface Velocity {shaft Ø (inches*.262) x rpm} (fpm)

What does AHPS PV Rating mean?

The AHPS PV rating is a way to match your application to a high pressure seal’s ability to handle the stress it will experience in your application. PV ratings are specific to product groupings as a way to compare seals within that grouping and aid in finding the best match. Within each product group on our website you will find a PV rating calculator to allow you to calculate the PV rating for your application. This will then allow you to see which seal designs could be used.

Why is it important?

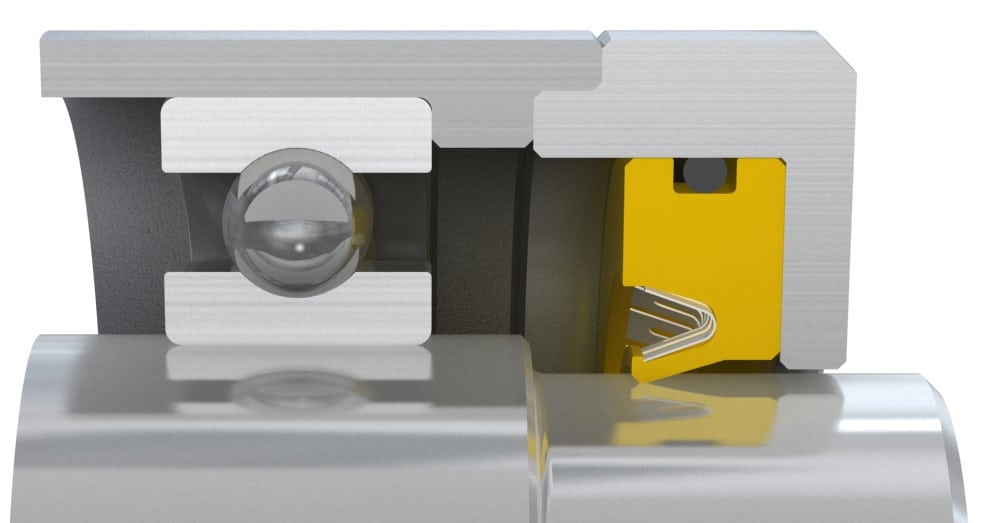

PV gives an indication of the maximum stress a seal can handle, as the real enemy is the frictional heat created at the shaft/seal interface as the shaft rotates in high temperature shaft seals. Beyond a certain PV, it becomes impossible to cool the shaft sufficiently to maintain the under-seal lip temperature within the acceptable range.

Can I use the PV limit to calculate my pressure limit at a certain RPM or vice versa?

No, the pressure and velocity limits of the seal material are fixed and do not change due to the PV number. For instance, seals have pressure limits that cannot be exceeded regardless of the shaft RPM. Likewise, seals have velocity limits that cannot be exceeded regardless of how low the pressure is.

If the PV number is the same, can I use the same seal regardless if the pressure is the dominant number or velocity is the dominant number?

No, high pressure damages seals in a completely separate manner than high speed does. This is why we have seals designed for three types of operating conditions for the same PV number: High Pressure Low Speed (HPLS); High Speed Low Pressure (HSLP); and Medium Speed Medium Pressure (MSMP)

Is the PV limit for a seal a fixed limit?

No, it is very application specific. Many factors can help or hinder seal performance in a high PV application: Extrusion gap; fluid viscosity at application temperature; eccentricity; run out; shaft surface finish; heat transfer; cycle length and frequency, etc. It is recommended that you consult with one of our engineers if your PV number exceeds 60% of the published limit.

Is there a standard test for establishing a PV limit on seals?

No, each manufacturer uses its own test; it may not even be a seal test, but a bearing material test. There is so much more to a PV seal design than the material’s PV limit. There is no way to compare one manufacturer’s PV limits with another’s.

AHP Seals is the Best Choice for High Pressure Seals

Whether it is for high pressure rotary shaft seals, high pressure oil seals or high pressure hydraulic seals, AHP can deliver for you. Our Seal Engineers have the necessary experience to recommend the best seal design for any high pressure/high temperature application. Call us at (800) 283-7140, or fill out our contact form on our Contact Us page.